We have a large production capacity

DELIVERY IN 10 DAYS FOR YOUR PROJECT

Manufacturing process

Custom

- Production of each independent support

- Custom molds required by the project

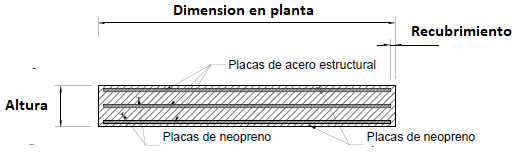

- Control of the arrangement process and thickness of plates and elastomer according to (PAC-BP)

- Vulcanization process

- Review of edges, tolerances and surface treatment of the final support

- Protection against corrosion

- Certification through tests.

International standards for application

- ASTM D4014 -Neoprene

- Physical Properties

- Hardness: D2240

- Tensile Strength: D412

- Heat Resistance: D573

- Compression Set: D395

- Ozone: D1149

- Instant Thermal Stiffness: D1043

- Low Temperature Crystallization: D1043

As manufacturers we are concerned with ensuring that the technical requirements of the design are met:

- Material specification

- Geometric specification and its tolerances

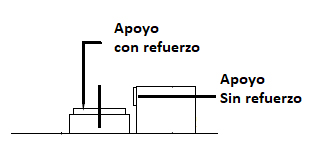

- Installation specification

Our Products

Provides manufacturing, supply and installation support services for new construction or bridge rehabilitation projects, delivering quality products customized to the needs of each client project.

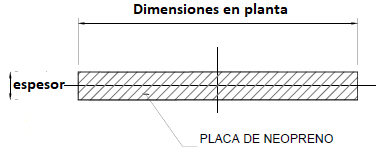

Elastomer

Shore hardness; 50-70

Shear modulus (G) kg/cm2: 6,6 - 21

Plastic flow deformation (%): 25 – 45

In the case of support devices, the ranges are higher, and are in accordance with ASTM standards

Tensile strength (psi): 2250

Ultimate elongation (%): 300 - 400

Compression deformation (%): 35

Ozone: No cracks

Nota: For special support devices, contact us